The Impact of Precision Machining on Product Longevity

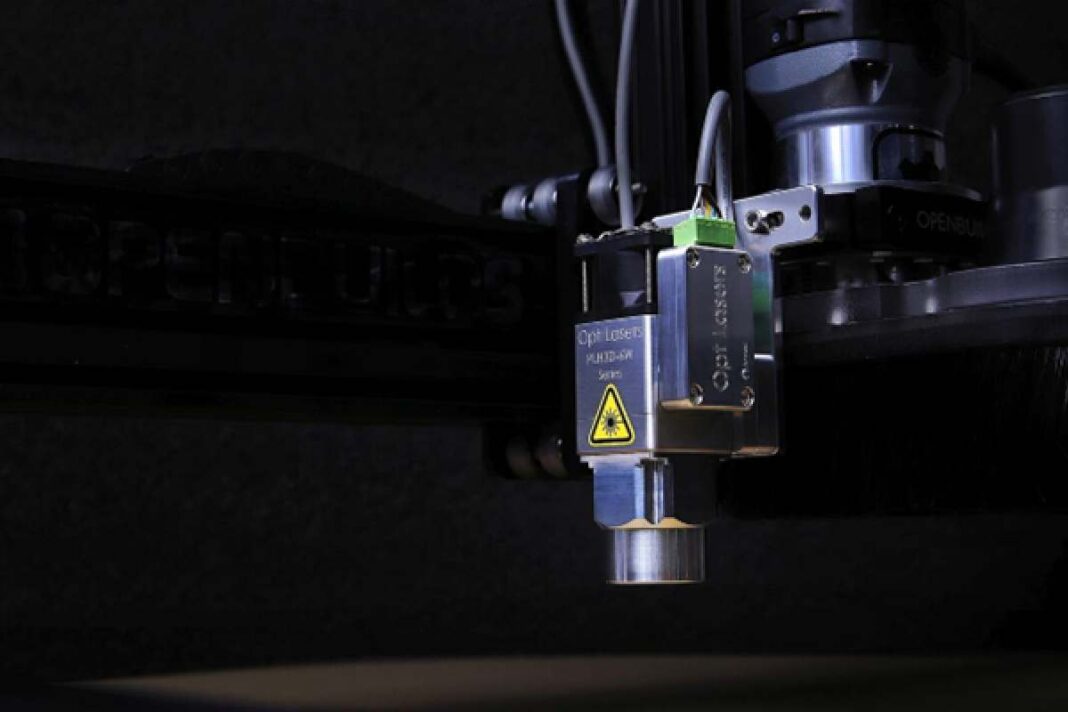

Precision machining produces parts and components with exact dimensions and finishes that meet strict design requirements. This method uses modern machines like CNC (Computer Numerical Control) machines, which create parts with high accuracy and consistency.

In industries where parts face heavy loads, heat, or harsh conditions, even slight deviations from design standards can cause early failure. Precision machining lowers these risks by ensuring every part is made within required tolerances. This improves the overall durability of the final product.

Importance of Machining Tolerance in Durability

A key factor in precision machining that affects product durability is tolerance allowed during production. Machining tolerance is the acceptable difference from a part’s stated dimensions. Simply put, it defines how much a part’s size can vary while still working properly.

In tough industries, tight tolerances are crucial to ensure parts fit accurately and function well. For example, in aerospace, where parts face extreme heat and pressure, small tolerance deviations can cause major failure. Keeping tight tolerances helps manufacturers ensure parts stay strong and reliable over time, resulting in longer-lasting products.

How Precision Machining Enhances Durability

Consistent Quality and Repeatability

One major benefit of precision machining is making parts with consistent quality. Advanced CNC machines are programmed to match design specs exactly, making each part identical. This uniformity is vital for product longevity because it reduces variability, which can cause defects or failures.

For instance, in the automotive industry, precision machining makes engine parts that endure heat, pressure, and vibrations. Making parts to exact specs reduces wear and extends engine life.

Material Integrity and Surface Finish

Precision machining preserves the strength of materials. Care is taken to avoid stresses or flaws during machining that can weaken the material. Techniques like choosing right cutting speeds, feeds, and coolants help keep material durable.

Also, the surface finish of a part affects its durability. A smooth finish lowers friction, wear, and corrosion risk, improving lifespan. Precision machining produces parts with high-quality finishes, helping them last longer under harsh conditions.

Fit and Functionality

How parts fit and work together affects durability. Precision machining ensures parts fit perfectly in assemblies requiring many components to work smoothly. This precision reduces mechanical failures caused by misalignment or poor fit, which cause wear and shorten product life.

In areas like medical devices, where parts contact body tissue or fluids, precise fit is essential for safety. Precision machining ensures components meet strict tolerances needed for such critical applications, increasing device durability and performance.

Resistance to Environmental Factors

Many products face harsh environments like heat, humidity, chemicals, or abrasives. Precision machining helps make parts that resist these without damage. By choosing proper materials and processes, manufacturers produce parts that withstand corrosion, oxidation, and environmental harm.

For example, in oil and gas, precision-machined parts in drilling equipment must keep strength and function under extreme conditions. Precision machining ensures these parts endure tough use.

Precision Machining in Demanding Industries

Precision machining is vital in industries where safety, performance, and reliability matter most. Examples:

-

Aerospace: Parts like turbine blades and landing gear must meet strict tolerances to handle flight strains and temperatures, improving durability and safety.

-

Automotive: Engine, transmission, and brake parts must work reliably under stress and varying climates. Tight tolerances make them durable.

-

Medical Devices: Requires highly accurate parts for patient safety and care. Precision machining ensures dependable performance.

-

Heavy Machinery: Construction, mining, and farming gear works in harsh settings and faces heavy use. Precision machining makes parts tough, extending machine life and reducing downtime.

Conclusion

Designing durable products is key in many industries. Precision machining is critical for achieving this by ensuring components meet exact specs and tolerances. It creates long-lasting products by reducing variability, protecting material strength, and ensuring precise fit and function. As industries demand better performance, precision machining’s role in improving durability will keep growing.